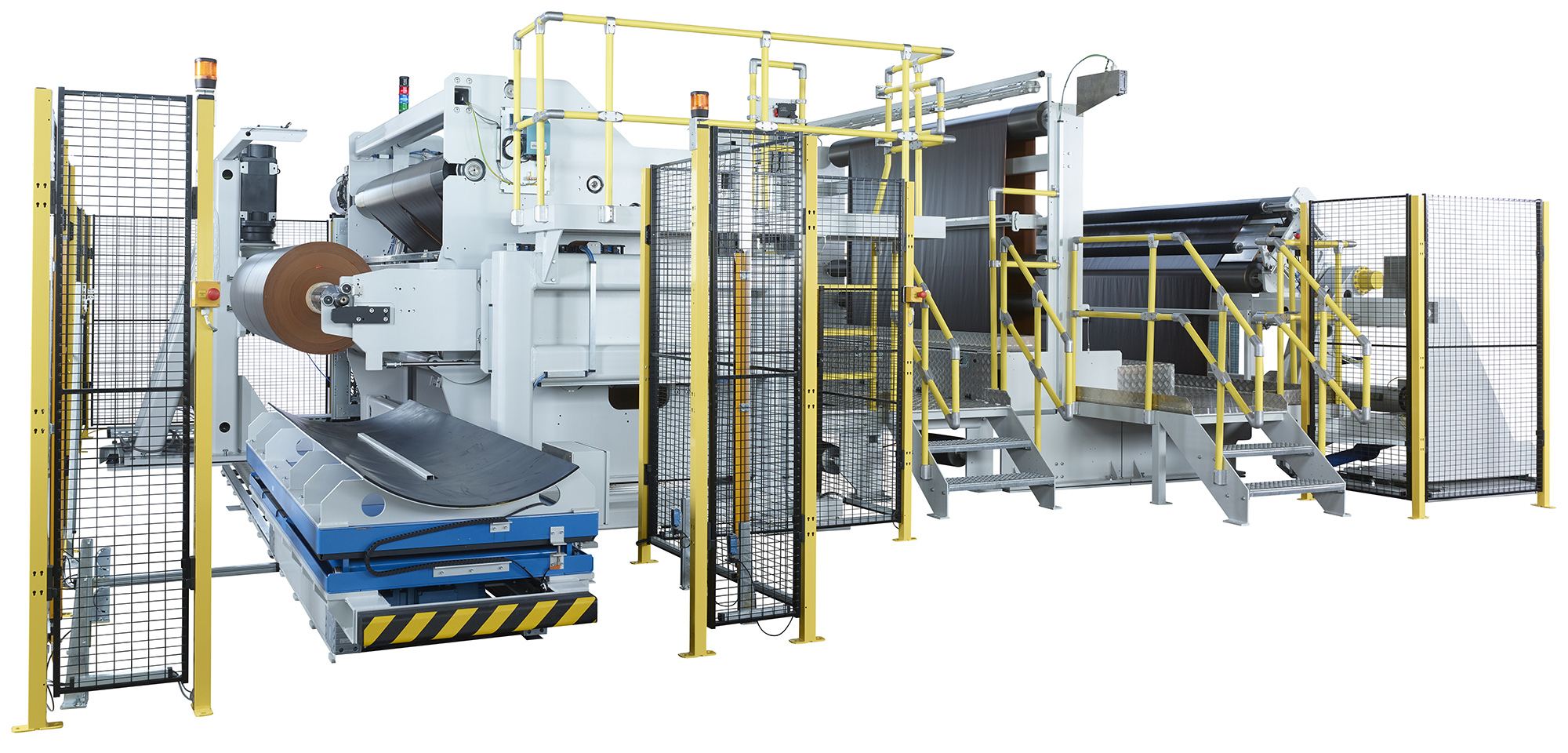

The SMBK-ECOSLIT was designed for precise roll slitting and winding tasks.

The winding takes place on a cantilevered winding shaft with individual center drives. A precisely working contact roller allows the optional winding in contact or gap mode. With increasing diameter, the contact roller is positioned horizontally from the winding roll. Due to the precise design, in combination with stepless control, SMBK ensures that the winding geometry remains constant during the entire winding process in order to achieve consistent winding quality across the full roll diameter. The well thought-out design as well as the individually developed drive technology for each machine ensure optimum cutting and winding Quality.