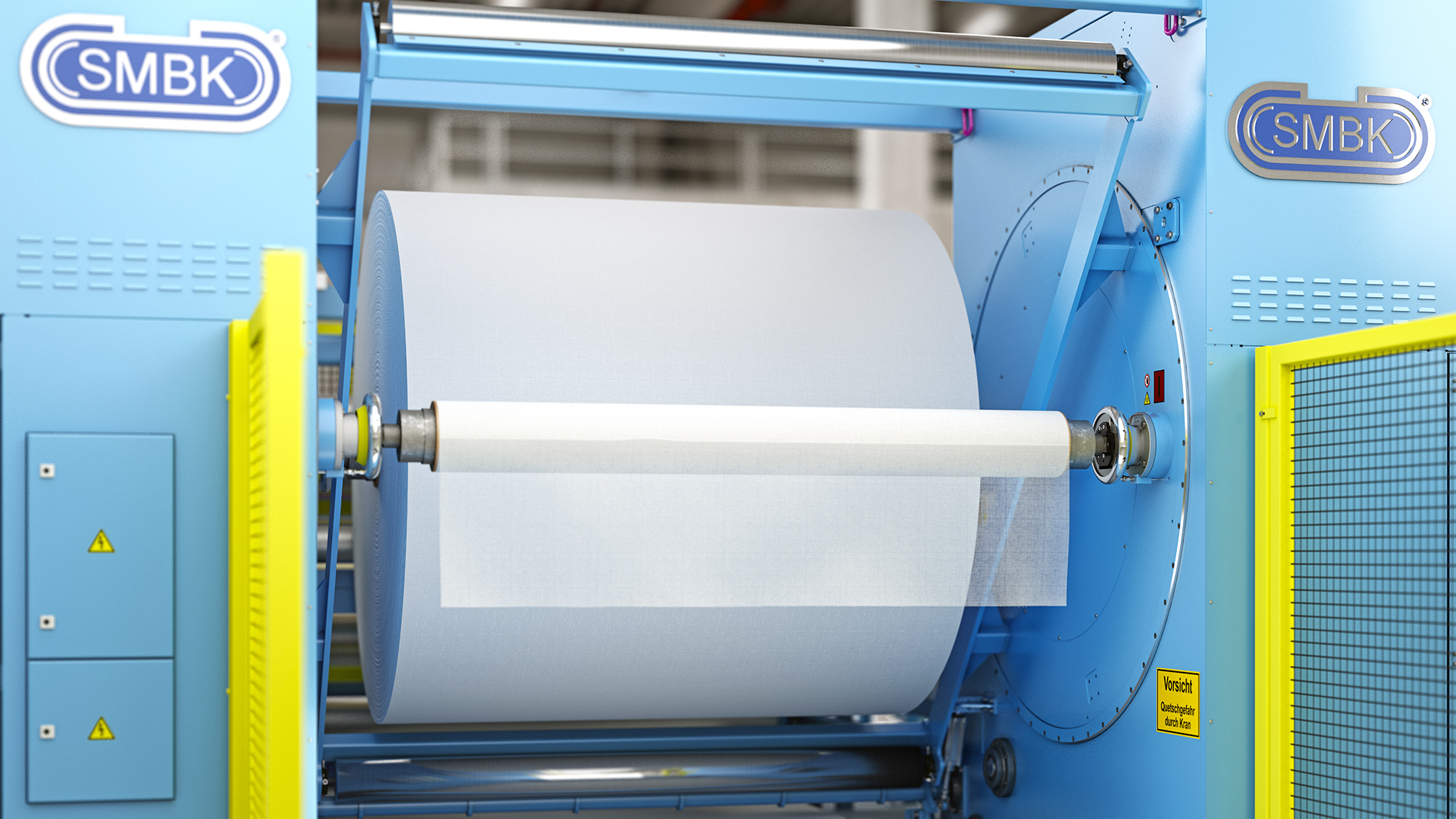

SMBK Big Roll Winders are used when products need to be continuously unwound or rewound. This can be used on a variety of different winding concepts. Depending on the application, the SMBK delivery program ranges from single-, to turret- and linear-winder. These are completed by systems for manual or automatic roll change. A reliable roll change at full production speed and optimized roll start quality is the Basic understanding of the SMBK Big Roll Winders. Depending on the customer's requirements, winding is done without shaft, on-the-fly or with winding shaft handling. The appropriate roll handling can be supplied or integrated by SMBK upon request.

- Big Roll Winder

- Short Roll Winder

- Slitter

- Roll Doctor

Applications

® SMBK

2026