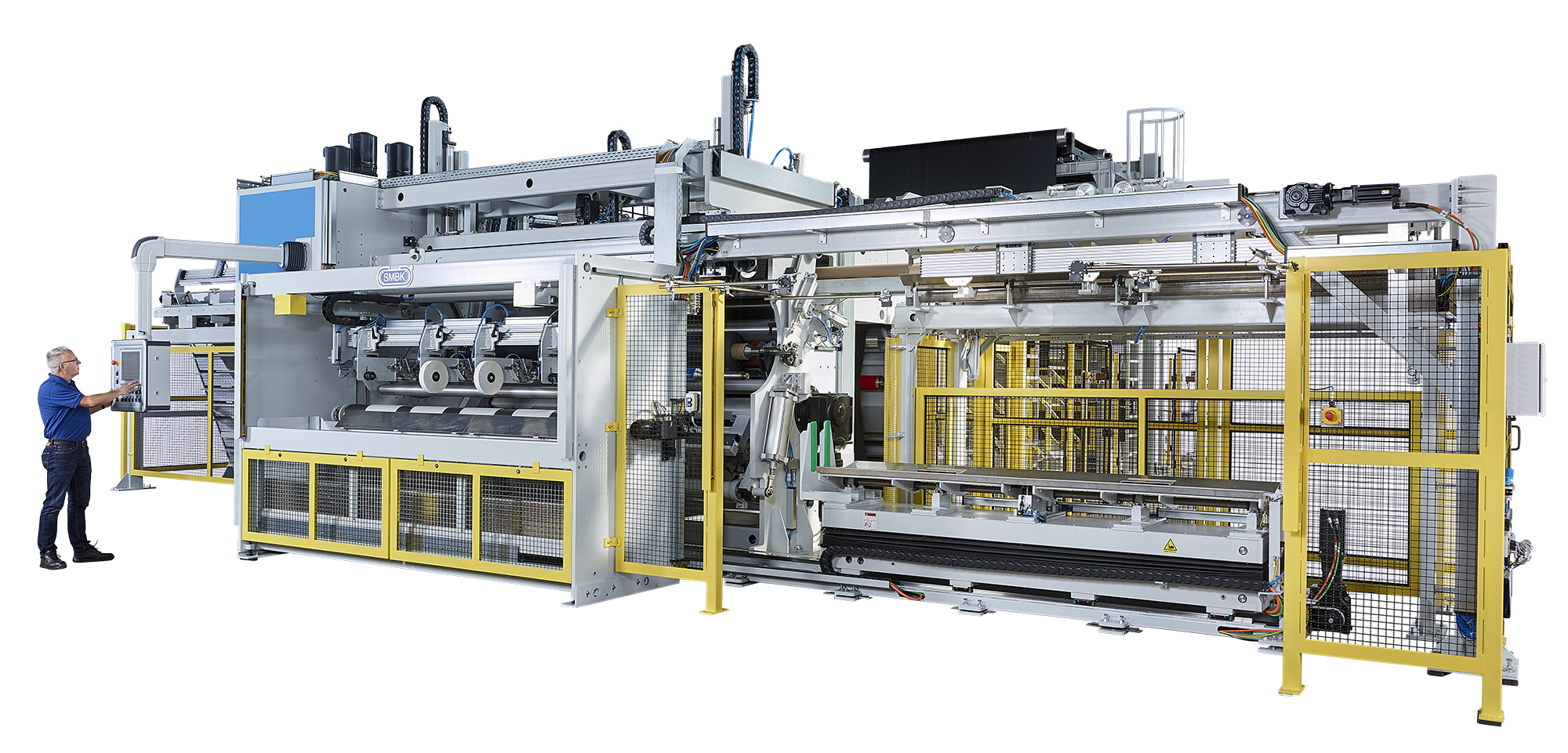

The SMBK-MULTIMAT is specially designed for the production of short rolls.

With the help of the three winding shafts, which are cantilevered mounted in a turret disk, this short-roll winder enables the production of high-quality short rolls with minimal downtime. The SMBK-MULTIMAT is characterized by high flexibility and reliable handling. Depending on the product requirements, the SMBK-MULTIMAT can be individually adapted to customer needs and process a wide range of materials: from thick composites to thin, sensitive papers.

The required cores are stored in a magazine and automatically fed to the winder. Depending on the configuration, the winding machine achieves the shortest possible cycle times. The range of configurable Options varies from the fully automatic cross tape applicator, over various application systems, to individual finished roll end closures and finished roll removal solutions. All based on an individual, reliable control for production-safe operation.

In combination with our proven accumulator technology, the SMBK-MULTIMAT can also be integrated in-line in production lines.